Would a custom-made cam with a more accommodating firing order do much to resolve this problem?Siamese intake ports would fill the two cylinders equally if the cylinders were 360 degrees apart in the firing order but that's not the case.

Figuring on a 240 degree intake duration, the intake duration for cylinder 1 follows the intake duration for cylinder 2 just as the #2 intake valve closes. Then there is a 240 degree lull in that Siamese port.

Same with cylinders 5 and 6.

Cylinder 3 and 4 do not share a port so the opening and closing valve port pressures are the same for both.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What Would be the Best of the Turbo Design's for Strictly a Drag Race Car?

- Thread starter bubba22349

- Start date

pmuller9, LOL that's great I like it! I was thinking it kind of looked like it was cut out with a hole saw or a Fly Cutter, nothing wrong with that its a very affordable way of doing it. I was also thinking yesterday that it might be good to do all the Intake ports the same for to equalize the flow, and maybe then even trying to raise up the exhaust Ports some too like they used to do on the Pro Stock 351 C heads.

Just for fun, here is some food for thought.

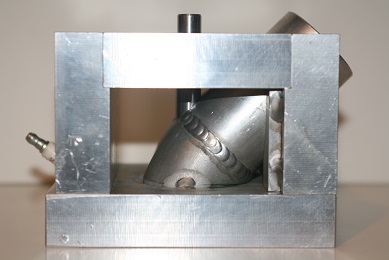

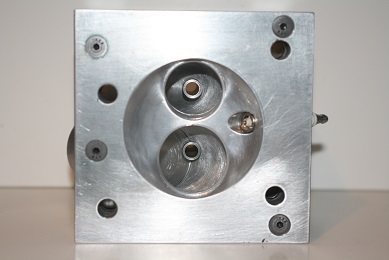

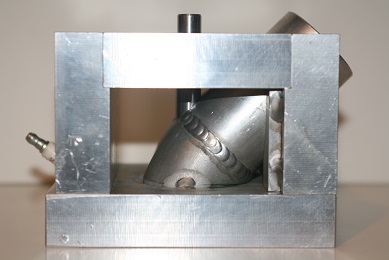

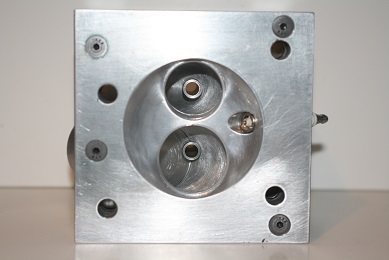

I did a Buick S8 one cylinder feasibility model from some rem aluminum in the corner of the shop.

The work was done in a mill by the machinist that owns the shop.

This eliminated the Siamese ports and got the valves centered in the cylinder.

Here is the continuation of the Buick S8 head evolution.

I don't know if this head was completed and run on the salt flats.

I did a Buick S8 one cylinder feasibility model from some rem aluminum in the corner of the shop.

The work was done in a mill by the machinist that owns the shop.

This eliminated the Siamese ports and got the valves centered in the cylinder.

Here is the continuation of the Buick S8 head evolution.

I don't know if this head was completed and run on the salt flats.

Last edited:

That sure is nice work on the single cylinder model I sure like that concept! Did you Flow test that against what a stock S8 Head would do? If a person could be able to machine up all those parts like and weld some it together so the Valves are centered like your in the cylinder that would have to make a very big change in its power potential. The 223 & 262 heads are also offset to the one side so that there is a ledge kind of like the old flathead Ford V8's and Bangers too. I have heard in the past that some wanted to try and move the 223 head over to center the valves more. I wonder what trouble there would be getting the Rocker Arms to work then? It looks like that S8 Bick might have a better Valve location stock compared to the 223 / 262 Heads. I really enjoyed see how he did the First and Second Generations that he ran and set records with.

With that type of plate construction he did in the Gen 3 concept it looks like an excellent designed Hemi chamber. You could do most any thing you wanted if you put in the time, like a Cross Flow Type Head with that Hemi Chamber or even go on to an Overhead Cam set up. His making it out of the layers out of Plate Stock is a pure genius design. is he maybe using some pins to aligning the parts or just using all the bolt holes and bolt them together he has pretty good access to weld up all the inside areas of the Intake & Exhaust Ports Tubes except on those sides that are tight together. If are going to be bolted together you could also take it apart again if you ever needed too. He is a great innovator and someone is also a very good machinist too. You said you didn't know if he got use 3rd Gen version on his S8 Bonneville Car? That sure would of been something to see any of those versions running.

I had another though to start looking at some other heads that might be adaptable like maybe the old Jag Six Over Head Cam Head. I also looked up what's offered at the local adult night schools here and its pitiful there is nothing for any type of Machine Shop or Auto Tech, about all that they have here LOL is to get a High School GED or Learn English as a Second Language, that's no help at all. Now need to find out if I can find someone that has shop equipment around here that I could make deal to use. Edited Thank you for the above post those Pictures and Video's of the different S8 head versions I really enjoyed it and its also very inspiring to me. He went into quite a lot of detail too I can see most of he how he was doing the process, except for how they were going to do the actual machining of the Hemi Combustion chambers.

With that type of plate construction he did in the Gen 3 concept it looks like an excellent designed Hemi chamber. You could do most any thing you wanted if you put in the time, like a Cross Flow Type Head with that Hemi Chamber or even go on to an Overhead Cam set up. His making it out of the layers out of Plate Stock is a pure genius design. is he maybe using some pins to aligning the parts or just using all the bolt holes and bolt them together he has pretty good access to weld up all the inside areas of the Intake & Exhaust Ports Tubes except on those sides that are tight together. If are going to be bolted together you could also take it apart again if you ever needed too. He is a great innovator and someone is also a very good machinist too. You said you didn't know if he got use 3rd Gen version on his S8 Bonneville Car? That sure would of been something to see any of those versions running.

I had another though to start looking at some other heads that might be adaptable like maybe the old Jag Six Over Head Cam Head. I also looked up what's offered at the local adult night schools here and its pitiful there is nothing for any type of Machine Shop or Auto Tech, about all that they have here LOL is to get a High School GED or Learn English as a Second Language, that's no help at all. Now need to find out if I can find someone that has shop equipment around here that I could make deal to use. Edited Thank you for the above post those Pictures and Video's of the different S8 head versions I really enjoyed it and its also very inspiring to me. He went into quite a lot of detail too I can see most of he how he was doing the process, except for how they were going to do the actual machining of the Hemi Combustion chambers.

Last edited:

Now I am thinking about this so you use a individual Fuel Injector for each of the new Intake Ports, and with the Twin Turbos would you pipe each one into its own separate Throttle Body or would you be better Y pipe them both into one bigger Throttle Body? Would you use a Crank Triger Ignition system too?

Yes, Individual runners with a fuel injector in each runner.

The runners go straight out into a large tube plenum with a single throttle body at the end of the tube plenum.

Look at minute 17.40 in this video.

Then watch this video.

I would use a crank trigger EFI system.

The runners go straight out into a large tube plenum with a single throttle body at the end of the tube plenum.

Look at minute 17.40 in this video.

Then watch this video.

I would use a crank trigger EFI system.

Last edited:

They had a difficult time (difficult is putting it mildly) getting the Gen3 head approved.With that type of plate construction he did in the Gen 3 concept it looks like an excellent designed Hemi chamber. You could do most any thing you wanted if you put in the time, like a Cross Flow Type Head with that Hemi Chamber or even go on to an Overhead Cam set up. His making it out of the layers out of Plate Stock is a pure genius design. is he maybe using some pins to aligning the parts or just using all the bolt holes and bolt them together he has pretty good access to weld up all the inside areas of the Intake & Exhaust Ports Tubes except on those sides that are tight together. If are going to be bolted together you could also take it apart again if you ever needed too. He is a great innovator and someone is also a very good machinist too. You said you didn't know if he got use 3rd Gen version on his S8 Bonneville Car? That sure would of been something to see any of those versions running.

I'm not sure if the plate steel head would be allowed to be used as a record holder. Maybe that's why there was no further reporting on it.

If you are looking to run the 262 engine as a Ford 262 engine, anything other than a head that is based on the stock head design kinda negates being able to say it is a Ford 262 engine.I had another though to start looking at some other heads that might be adaptable like maybe the old Jag Six Over Head Cam Head.

It is pitiful what the Vocational Trade school offerings have become.

Wow the Jeep Engine Builds are really something to! And the Turbo version is truly amassing for what looks to be a simple build up of the Short Block and Head Work I can tell he spent a lot of time on the important details. That Intake is got to be a big factor along with the Heads Porting and Valve sizes. I wonder how much all the electronic EFI and the Crank Trigger system moved the bar too probably a lot. I only used the conventional Race Moded Holley Carbs and an MSD Box.

Newcomer racing certainly did it right and I have no doubt they can hit the 1000 hp mark.

They were using the Holley Dominator EFI system.

IMO a Holley HP would have handled everything they needed to control the build.

What is really great is that Holley makes available all the matching sensors and other accessories that work with their EFI systems.

I was disappointed with the results of the Power Nation 300 six turbo video.

They had the opportunity to make over 700 hp but had a mismatch between camshaft and turbocharger.

They would have also needed the Molnar or Compstar rods with a lower compression piston.

With the modified 12 port 262 head the engine should be able to make as much power as the block and crank can take.

What do you think the power limit would be?

They were using the Holley Dominator EFI system.

IMO a Holley HP would have handled everything they needed to control the build.

What is really great is that Holley makes available all the matching sensors and other accessories that work with their EFI systems.

I was disappointed with the results of the Power Nation 300 six turbo video.

They had the opportunity to make over 700 hp but had a mismatch between camshaft and turbocharger.

They would have also needed the Molnar or Compstar rods with a lower compression piston.

With the modified 12 port 262 head the engine should be able to make as much power as the block and crank can take.

What do you think the power limit would be?

Last edited:

All those Blocks are surprisingly very strong I sure wasn't making much power back in the late 1960's as a teenager but I pushed them really hard never Damaged even the early blocks 1954 to 1960 223's, those had a poor oiling system. On the 223 the two Main Weak Points are the Stock Rod and Piston The Cylinder Walls are very Thick too it was not uncommon for them to get bored out .060 to .120 during the many rebuilds during their lifetimes. The 1961 to 1964 223 Block's had an improved Oiling system, same as the 1961 to 1965 262 Blocks which are even stronger yet with an extra 20 Pounds of extra Ribs and Main Webs Cast into them. At 6000 or more RPM the Bonneville Race 262 did not break any of the Main Webbing or damage the Crankshaft. It looks like the Cylinder Walls were the weakest point in his engine and I still don't know how far he had bored it out. He had said that he was going to use the block Grout in it up to 2 inch below the deck, but then I guess he decided not to after some comments by others that had used that product that it would cause movement of the Cylinder walls around since the Block had all ready been completely machinated with the bore and finish honing to the size. He had also built a Block Gridle for his first engine combo but later on when he was lowering the front of the truck more for better Air flow over it he took it out. These blocks have very Deep Side Skirts like on the old Y Block and FE V8's, I would think that some custom Main Caps could be made where you could then Cross Bolt the Mains to the side skirts like they did on all the 427 FE Blocks, then a simple block Gridle could also be added to so that Bottom end could handle lots more than the power then you could probably make. I would say with the good BB Chev Rods and a good set of Forged Pistons north of 600 HP should be doable. No luck yet in finding a 262 Six I did locate a 1961 or 1962 223 Engine Core, its one of those that Ran sorta when it was pulled out with maybe has a bad Head Gasket or???? It's all ready been Bored out to .030 over with a .010, .010 Crankshaft according to the Stamped Metal Rebuilder's Tag.

I second the Holley HP, should be able to find one used for a good price. Some people find that they what to do more and upgrade to the Dom. and sell their HP. Harness is the same and you can do the same if you find you need more. You should be fine with the HP.

Thank you drag-200stang, I guess I would needed to be schooled on which one of the Holley HP Kits to look for what do they use for port injector's?

The port injector size is determined by which type of fuel you use and the peak horsepower.I guess I would needed to be schooled on which one of the Holley HP Kits to look for what do they use for port injector's?

Holley prefers Accel injectors, but any brand will work.

This is the Holley HP universal kit with the better NTK oxygen sensor.

It can be configured for 4, 6 and 8 cylinder engines.

There is also an Unterminated universal kit that will allow you to custom make the wire lengths for a much neater wiring job.

This kit would work for Racing gas and E85 and Methanol.

Holley EFI 550-604N HP EFI ECU & Harness Kits

Looking for a plug and play alternative for your stock or built late model factory EFI engine? How about a replacement ECU for your older Holley C950? Holley has you covered. HP EFI ECU and harness kits are designed to be used with popular factory EFI engines as an alternative to the factory ECU...

Last edited:

Similar threads

- Replies

- 18

- Views

- 745

- Replies

- 5

- Views

- 443

- Replies

- 13

- Views

- 899