Mattsmall1972

New member

Hi all - I am new to this as I just purchased a 1966 Mustang with the 200. I’m doing a mild build. The plan is:

Holley Sniper 1100

HEI distributor

Headers/dual exhaust

Schneider 256-2H cam

Large log head

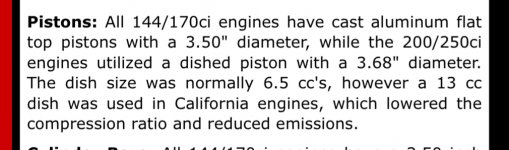

I have purchased a 1977 large log head from ebay. Assuming it’s stock head, I am looking for milling information.

1) Do I tell the shop the ccs that I need and have them figure it out? If do, what is that number for my build?

2) Are there any recommended machine shops in SC for this work?

3) Are the stock springs and valves sufficient? If not, what’s recommended?

Thank you!

Holley Sniper 1100

HEI distributor

Headers/dual exhaust

Schneider 256-2H cam

Large log head

I have purchased a 1977 large log head from ebay. Assuming it’s stock head, I am looking for milling information.

1) Do I tell the shop the ccs that I need and have them figure it out? If do, what is that number for my build?

2) Are there any recommended machine shops in SC for this work?

3) Are the stock springs and valves sufficient? If not, what’s recommended?

Thank you!