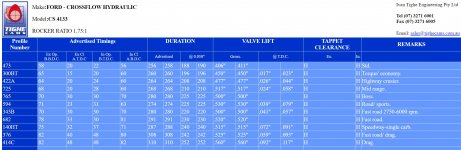

Ok, the alloy heads started around 1980, there are some differences I dont know of them all, but they are identified by a cast in letter and number on the front LHS under the intake ports. Basicly there are two valve size heads, small valve has 1.75 1.50 valves, big valve heads have 1.85 1.54, the ports all look the same with one exception, early heads dont have a cutout for the fuel injector in the top rhs of the port. There are combustion chamber differences, earlier heads were open chamber like the one I have, later ones have a smaller chamber with a swirl inducing "wing" this was when the engines went to unleaded fuel. The blocks are pretty much all the same, the very latest 1986 ones have a lip seal on the rear main. Pistons vary in that, 200ci engines have flat tops which I use. Later 250s have dished pistons, and unleaded pistons have a canyon on the top to reduce CR, they also have 1mm rings for reduced ring friction, these break from time to time. All pistons were branded as FORD from the fatory, but made by ACL under Repco, which supplied most bearings etc for the engines made here. As you probably know nobody here would bother trying to fit a crossflow head to a pre crossie block, the crossflows are quite common in 250ci less common is the 200ci. The 200 has the longer rod at 6.27inches, the 250 5.88. The later AU SOHC engines went to a long rod with short skirt pistons to help with NVH, and they will rev quite well, Ive had one. Of course the DOHC Barra engine being 4 valve and DOHC revs well, they went up to 192kW in NA form, 310 in turbo form. Barra nad SOHC engiens are bullet proof. The crossflow engines is quite commonly tuned and cam and valve train bits are fairly easy to come by, Crowcams do several in hydraulic and solid, I run a small hydraulic made by Camtech specially for my engine, the stock cams are nothing special, and will generally only run to 4500rpm, I run a 215 @0.050 cam which will run to 5000 easliy, I dont go above that as this is about where my blower reaches its rated speed limit of 15000. Although i know of others that have run them to 21000. Rockers are cleveland sled type, we used mostly sintered iron pivots down here, they seem to be OK to 6000rpm at least, retainers and springs are again crowcams, they have a website. Stock reatiners vary, most are sintered, but some are steel, we dont use them. Lockes are the multi groove ones and are ok, Ive uesd they on higher RPM clevelands by grinding them so they dont allow the valve to rotate, its a cheap fix that seems to work. lifters are the common ford thing so no real issues there. People have used roller cams by using 460 flowers and special tie bars. the best BHP Ive heard of out of a 250ci was 365NA with a 4barrel carb and extensive head work. The ports are high in th head and quite nicley shaped to come down vertialy over the intake, exhaust ports are very nice and need no work. Not many people run the 200ci as its doesnt have the torque that the 250 does, and by the time you get the crossflow head working really well they will rev to 6500. Bottoms ends are bullet proof, the oil pump is good, and replacement iron pumps are available localy here, HV is not needed. There was a cast iron crossflow head in 76, but they are so heavy nobody goes near them. Overall the crossflow is a tough unit and widely used. The SOHC is commonly used but now most people are tuning the barra, its a big heavy thing that is as tough as old boots, dirt cheap, and can make huge torque with boost its only fault is the crank driven oil pump which has sintered gears that can fail, but steel gears are available for that. Even the stock rods and pistons with go to around 600bhp, people have achieved this sort of power without lifting the head. There is no aftermarket blocks and heads, but nobody seems to need them. A stock barra from a wrecker will cost you about $500 and would be a good runner at that. Hope this give some insight. Ps I forgot about cranks, the 200 crank has the shorter stroke and is lighter of course, the 250 is bigger for the 3.91 stroke, they are all good quality Nodular iron and never fail, theere are stories that the Australian made stuff is supeior to the USA because we have better raw materials?? The later 250 cranks have more counterweights. In the Au model they enlargded the mains journals again to get smoother running, the barra has this setup. The Au engines were the last one to have a jack shaft and oil pump in the sump. Psitons seem to be pretty gppd from the factory, they are all cast, mostly ACl, but I think turbo ones are Mahle. we also have dedictaed LPG engines, these run really well and were quite popular, Ive had one it was really good, they last forever.