Pmuller9 has been graciously donating his time in researching to find some better parts that could be used in building a High Performance 223 or 262 short block. This has led to what looks to be a very good combo for an aftermarket Connecting Rod and Custom Forged Piston from Auto / Race Tech to use in these six's, this is one of the weaker links that I personally found in these engines when racing them. Didn't kick any rods out the side of a block but knocked out some Rod bearings and coming real close to it.

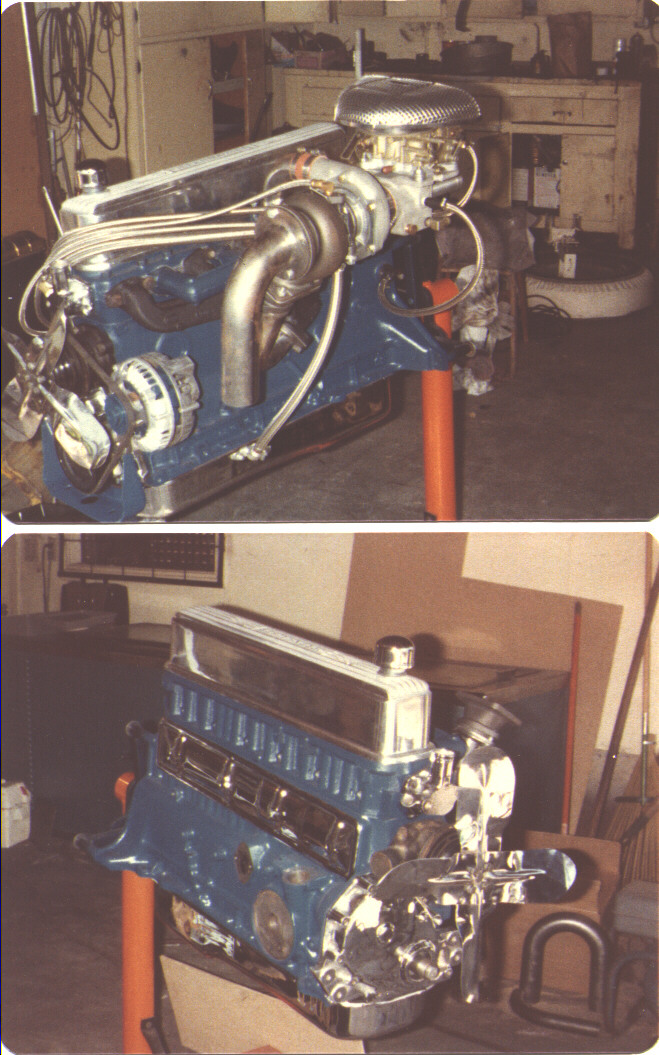

This morning I also came back across some info and pictures of an old 223 Turbo build by our site member "curts56", so decided to use it as some of the inspiration for the start of this 223 build up. Below are the posts I was able to find were curts56 talked about his 223 Turbo engine. Evidently this is the only Turbo 223 build that's been documented on the Ford Six site. I also like it that he still has 1956 F-100 pickup that he used it in, these pickups have always been a big favorite of mine and is was what I learned to drive in and started racing with.

[Quoted by Curts56]

"Yes I'd do it again. The turbo I used was a Rotomaster T04B. It was part of a universal inline six turbo kit that Rotomaster once sold (Turbo #710250, installation kit #720001). The kit came with most of the pieces such as turbo, boost controller, J-bend tubing, gaskets, oil lines, etc. Being a universal kit meant you had to do some fabricating. Here is a list of engine parts I used (fuzzy memory):

Rods: Stock – shot peened

Crank: Stock – shot peened

Pistons: Sealed Power

Cam: Iskenderian

Carb: Holley 350 2bbl.

Valves: Chevy – Larger than stock 223.

I used water injection to prevent detonation. I also ended up fabricating a head gasket out of a sheet of copper after blowing a few stock ones. Probably O-ringing the head or block would have prevented that. If you are not looking for a high HP six then the 223 is a great engine. Curt"

"

[Quote by curts56] on May 24, 2004. "Those pictures are of the engine that was in my 56 F-100 20+ years ago. It ran really great until the boost controller started sticking and allowed the boost to get up over 11lbs. That was really fun till a connecting rod snapped and blew holes in both sides of the block." From what other info I found that curts56 stated this means his Turbo system was used back in around 1978 or 1979 in his 1956 F-100..

[Quoted by curts56] on July 7, 2019 regarding a proposed 223 Tubo build. "You'll probably be ok if you keep the boost down around 8lbs or less. I busted a connecting rod on my turboed 223 when the boost got up to around 11lbs"

The Curt56 223 Turbo Build 3 More Pictures of His Draw Through Turbo

Sounds like it was quite a fun little engine and I wonder why no one else here has built another Turbo 223. Edited

This morning I also came back across some info and pictures of an old 223 Turbo build by our site member "curts56", so decided to use it as some of the inspiration for the start of this 223 build up. Below are the posts I was able to find were curts56 talked about his 223 Turbo engine. Evidently this is the only Turbo 223 build that's been documented on the Ford Six site. I also like it that he still has 1956 F-100 pickup that he used it in, these pickups have always been a big favorite of mine and is was what I learned to drive in and started racing with.

[Quoted by Curts56]

"Yes I'd do it again. The turbo I used was a Rotomaster T04B. It was part of a universal inline six turbo kit that Rotomaster once sold (Turbo #710250, installation kit #720001). The kit came with most of the pieces such as turbo, boost controller, J-bend tubing, gaskets, oil lines, etc. Being a universal kit meant you had to do some fabricating. Here is a list of engine parts I used (fuzzy memory):

Rods: Stock – shot peened

Crank: Stock – shot peened

Pistons: Sealed Power

Cam: Iskenderian

Carb: Holley 350 2bbl.

Valves: Chevy – Larger than stock 223.

I used water injection to prevent detonation. I also ended up fabricating a head gasket out of a sheet of copper after blowing a few stock ones. Probably O-ringing the head or block would have prevented that. If you are not looking for a high HP six then the 223 is a great engine. Curt"

"

bigsix:2axw4wtt said:Check this out!!! It's a turbo 223;COOL!!!

[Quote by curts56] on May 24, 2004. "Those pictures are of the engine that was in my 56 F-100 20+ years ago. It ran really great until the boost controller started sticking and allowed the boost to get up over 11lbs. That was really fun till a connecting rod snapped and blew holes in both sides of the block." From what other info I found that curts56 stated this means his Turbo system was used back in around 1978 or 1979 in his 1956 F-100..

[Quoted by curts56] on July 7, 2019 regarding a proposed 223 Tubo build. "You'll probably be ok if you keep the boost down around 8lbs or less. I busted a connecting rod on my turboed 223 when the boost got up to around 11lbs"

The Curt56 223 Turbo Build 3 More Pictures of His Draw Through Turbo

Sounds like it was quite a fun little engine and I wonder why no one else here has built another Turbo 223. Edited

Last edited: