MeanGreen&Fireball

New member

Okay, I’m completely new to the world of forced induction. I’m reading as much as possible but a lot of this is just estimating what might get me in the ballpark of a fun ride. I’m asking for help and guidance from the group that knows more than I do. Will this turbo work well on the 200 and which cam would be the best option?

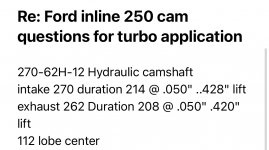

I’m running a 200cid, with mostly stock components. I have a 78 large log head, non-ported with stock valves and stock springs. I know I’ll probably have to change out springs to accommodate the new cam. I’m not looking for the 200 to make all its power on the top end since I doubt I’ll be in that RPM rang much.

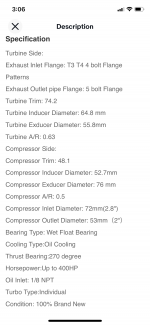

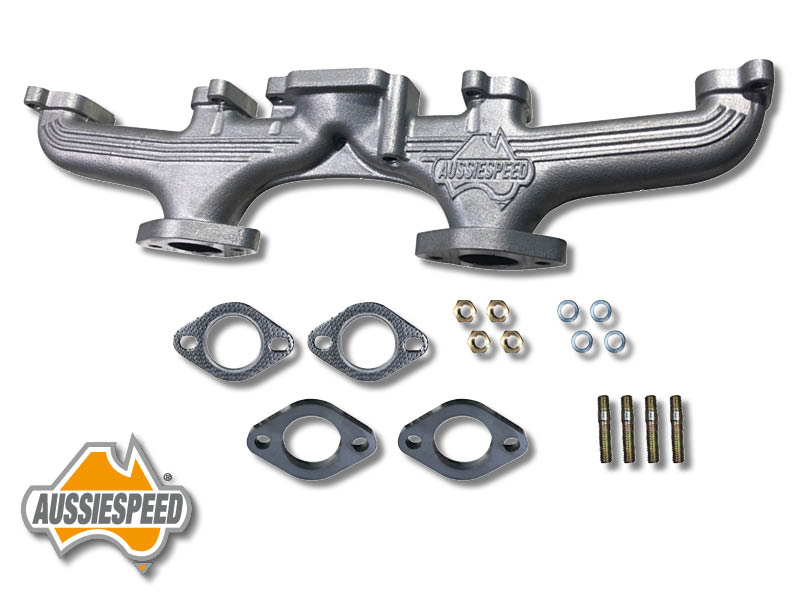

I'm having a exhaust manifold built to accommodate the turbo. I’m having an issue choosing the cam and turbo set up. This is what I found so far. This is not the ultimate build for me, this is just an intro and learning experience to forced induction for me. I found two cams but which one is best? I would like the cam to have just a tad bit of lope for fun and a turbo that Will spool pretty quickly. I want to run 8-10 lbs of boost…. Nothing crazy.

I’m running a 200cid, with mostly stock components. I have a 78 large log head, non-ported with stock valves and stock springs. I know I’ll probably have to change out springs to accommodate the new cam. I’m not looking for the 200 to make all its power on the top end since I doubt I’ll be in that RPM rang much.

I'm having a exhaust manifold built to accommodate the turbo. I’m having an issue choosing the cam and turbo set up. This is what I found so far. This is not the ultimate build for me, this is just an intro and learning experience to forced induction for me. I found two cams but which one is best? I would like the cam to have just a tad bit of lope for fun and a turbo that Will spool pretty quickly. I want to run 8-10 lbs of boost…. Nothing crazy.

Attachments

Last edited: