No, Volumetic efficency drops out of the equation. The cam builders set the maximum power rpm on an assumed VE. Go to Crow cams, and see how the power rpm and maximum engine speed change as you go up engine VE and cam stage.

Hence, the whole engine is assumed to have the power at the rpm given.

Eg, an XF EFI Falcon has a cam of about 264 degrees, and 162 hp at 4000 rpm, with an rpm maximum of 4500 rpm.

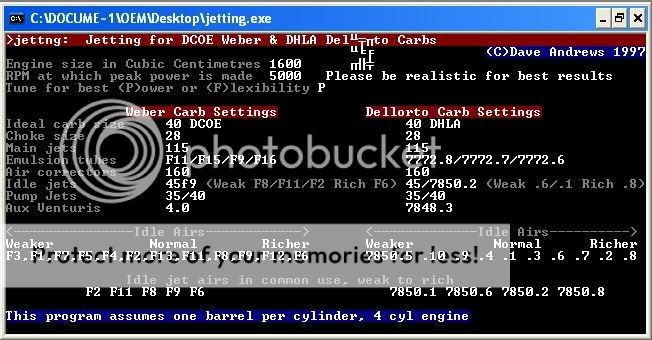

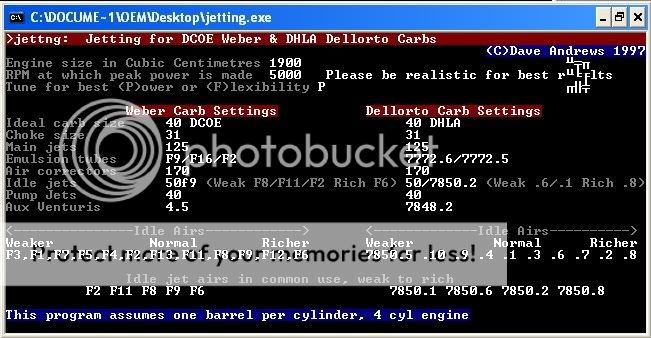

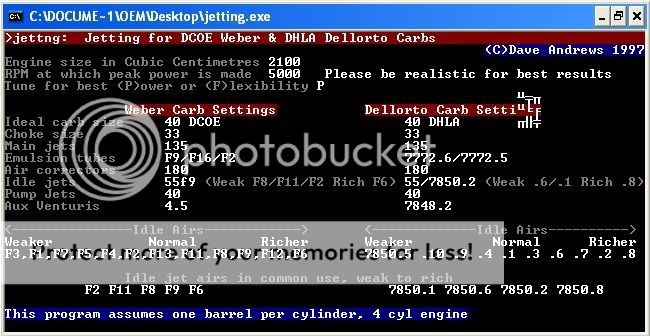

If it was saddled with a 2V carbed or EFI or independent runner set-up, the peak power band would still be 4000 rpm. pOWER WOULD BE ABOUT 150 with a carb, 162 hp with EFI, and about 185 hp with triple DCOE 45 or 40 Webers and 34 mm venturis or chokes. So VE may improve 15% with triple Webers over an LE-jetronic style EFI, but the power peak RPM stays the same. The cam sets the heartbeet. Looking at Hot Rods old 350 engine with any type of carb system proves that.

Anytime VE improves, and you do nothing else, the engine gains power. Its a David Vizard rule, and rpm is not a factor unless you have improved VE by the cam.

One of the reasons I like IR systems is that you get VE for free, with no cam or head mods, just a triple carb intake with the right sized chokes.

Put another way, the Indicated Brake Effective Mean pressure improves at any given speed if the VE improves. I can prove that by taking any given engine and do this

Take maximum power peak, and multiply it by any cubic capacity, and divide it by maximum power rating.

The result is an Aspiration Ratio. Any time VE improves, the engine makes more power per cube, without automatically needing more revs.

Eg (249.5 cubes times 4000 rpm)/162=6160, a pretty lame indicator of a very low stressed engine.

Stock EFI cams on XF engines with no other changes show 150 hp or so with ease,

so Aspriation Ratio is (249.5 * 4000)/150 =6653

Triple Webers, (249.5*4000)/185 = 5395.

By inspection or proportion, if a stock 250 with 2-bbl and EFI cam has a VE of 75%, then with EFI, its 81%, and with triples and no changes, its likely to be 93.5%. No change in peak power revs because the carb is pulse tunning the intake charge hard into the cylinder. So this is where I get the 25% gain minimum for an IR set-up on a 2-bbl set-up, mainly becasue all the bends, the time of concetration from the centre branch of the engine to the out ends is no equal. Compared to EFI, you get shortened intake runners, and more power due to the fourth order ram tuning, were gas speed is no longer super critical, but is able to operate in alternating current wave in a partial fuel standoff situation, where the gasses are pulse tuned like on a big tunnel rammed Prostreeter. If you've seen videos of IR cars (like Mazda rotaries or Mini 1275's with IDA's, or Harley motorbikes with Mikuni 42's), at wide open throttle, the fuel stands

above the venturi in a haze of hydrocarbons. Its a hall mark of the right tuning at or near wide open throttle. This is why velocity tubes and stubstacks, or adding metal plates 3/8" from the carb mouth help maximum power by containing the fuel standoff in carbs.

Anyway, the right IR carb venturi creates more power than injection at the same revs because of pluse tuning, and this was observed by Ford in the developement of the 250 Falcon six in both USA and Australia in the late 60's by engineers. We see it today in Toyota TRD race engines. Only reason they run EFI is for tuning and advancement, not because EFI makes more power.