I've just got done on a live feed where a renown Physicist tutor with years of development work at Holley stated all Holley carbs are rated Wet Flow. And he told me that the always were rated Wet Flow, all ways Have Been, because they had wet testing 5500 CFM flow boxes. I'm a bit preplexed.. Based on what I've seen, this is categorically and historically wrong about airflow being measured wet. SAE J228 air flow was ratified in 1971. Before then, everything automotive in the US was for sure measured dry and still is today when flow benched on SF 600s,700s, 1020s etc.

I cited the 585 wet flow CFM for the 4180C Holley 4bbl is know to be 630 CFM dry. Quoted Ford Motor Company' 1983-1987 5.0 and 5.8 liter 4bbls from two sources.

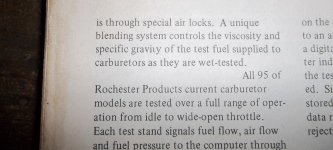

The one size of large 4MA QuadraJet 4bbl is rated 725 CFM wet, and 800 CFM. Quoted from GM-Holdens HDT engineering assistant Larry Perkins in 1987.

Everything before 1971, everything was dry flow at a nominated 3.0, 2.0, 1.85 or 1.5 inches of Mercury Head pressure drop at an agreed average mean sea level, humidity and temperature.

Anyone Agree/Disagree.

Thoughts?

I cited the 585 wet flow CFM for the 4180C Holley 4bbl is know to be 630 CFM dry. Quoted Ford Motor Company' 1983-1987 5.0 and 5.8 liter 4bbls from two sources.

The one size of large 4MA QuadraJet 4bbl is rated 725 CFM wet, and 800 CFM. Quoted from GM-Holdens HDT engineering assistant Larry Perkins in 1987.

Everything before 1971, everything was dry flow at a nominated 3.0, 2.0, 1.85 or 1.5 inches of Mercury Head pressure drop at an agreed average mean sea level, humidity and temperature.

Anyone Agree/Disagree.

Thoughts?

Last edited: