That's good progress!I set the timing per the shop manual, and found that I was 180 degrees off. I reset the distributor and wouldn't you know it, she fired up. It took me awhile of adjusting the distributor, idle speed, and mixtures but I got her to idle without the choke being on. It is still high at 850 RPM but it is a start. I have a vacuum gauge hooked to the intake manifold and it is telling me I have a vacuum leak somewhere. The needle keeps moving back and forth and should be steady. So I am going to check for vacuum leaks again and see where that leads me.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Weber 38/38 DGS and various Distributors

- Thread starter Sickboy49

- Start date

Sickboy49

Well-known member

Frank,That's good progress!The vacuum needle will twitch if it's reading form a runner where the pulse is strong. A carb manifold port is best for accurate net vacuum. Or in the plenum, as near the carb as possible.

Thanks for that advice. The port on the manifold is directly in the middle of the runners and underneath the carb. I have a secondary port on the carburetor that is not ported. I will get a picture of where I have it currently and the port on the carb itself. Making a new gasket for the carb adapter plate to the manifold tonight since the current one seems to be worn out.

Sickboy49

Well-known member

I wanted to give you guys an update. I thought there might have been a vacuum leak on the intake/exhaust gasket, so replaced that. It did nothing to help steady the vacuum gauge needle. Messed with the timing some more and idle speed/mixtures. She is running but it is not per the numbers or perfect by any stretch of the imagination. I am just going to tidy up a few things and then I am going to drive it and see what happens. Once I get it on the road (today hopefully) I am hoping whatever issue I may be having makes itself clear. I will keep you updated.

PSIG

Well-known member

Your timing is fighting itself (and you). The following assumes the distributor is functional, installed properly, and both points sets adjusted properly.With 30 degrees timing the vacuum is still reading low/late timing.

In order to avoid pulling your hair or causing problems, look at distributor timing as 4 sections:

- base timing (warm curb idle)

- centrifugal advance (increasing with rpm)

- total timing (wide-open high-rpm "all-in")

- vacuum timing (partial throttle added advance when distributor vacuum is present).

Example - if base timing(1) is 15°, and centrifugal(2) is 21, the total(3) is 36°.

YES, you can change base timing(1) to test a specific area as it affects all areas, but once the best timing is found for the target area, the others should be altered to maintain their original or best values. This avoids pooching the other areas when changing one of them. I suggest setting initial timing on first start by the total(3) (say, 36°), regardless of the idle timing. To do this I verify timing marks (or timing tape) to at least 50° BTC, disconnect and plug vacuum, strap or chock and start in P or neutral. Set any reasonable base timing(1) (10°-14°) for warmup. Adjust idle for reasonable rpm as it warms.

Watching timing with the timing light, I smoothly rev the engine until no more centrifugal(2) advance is added, then set the total timing(3) at that point, e.g., 36°. Let it idle-down, set warm idle rpm, and check the idle timing(1) that results. Now you know actual #1 and #3 as the distributor is set now, and can work from that baseline. Leave vacuum(4) disconnected until 1, 2 and 3 are set to best values, then you can tune vacuum advance on ported vacuum. To use manifold vacuum will require additional adjustments of 1-3. Hope that helps as a first high-level overview procedure.

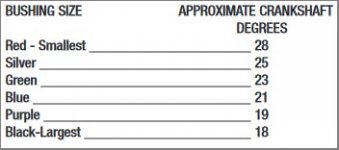

[EDIT adding Holley centrifugal advance limiter bushing chart}

Last edited:

Sickboy49

Well-known member

I agree that they are independent of one another. I got it running good enough on a second attempt. Base timing is still around 20. I am going to perform a leak down test tonight, to see if any of the valves are not completely closing on the compression stroke. I was lucky enough to have my local mechanic let me borrow his setup, after describing the issues to him.What was the distributor setup and timing you gave it for the drive? As fuel and ignition issues are interdependent, it's good to put one to bed so any issues with the other are clear.

PSIG

Well-known member

Bummer about the rebuild, but good you found possibly related issues. Just a note that "Base timing is still around 20" means the smallest (black) bushing will be needed to keep the expected total timing in-range. 20 + 18 = 38°. Excessive advance can induce bucking and jerking, either from the total advance (base + bushing) or the rate of advance (weights and springs), or both. Could that be what you feel?

Sickboy49

Well-known member

So another good news bad news post.

First the bad.... I performed a leak down test on the motor yesterday dry/wet. On the dry test I found cylinders 1 and 3 to be perfect however 2,4,5,6 were only at best 65%. I had a stethoscope and was listening for blow by on the valves with no luck. On the wet test all cylinders were good. So that tells me the molley rings haven't seated yet.

Good news... I got the motor up and running and took it around my test loop twice. Initially I had the same stumble and hesitation at low RPM, but got it better with adjusting the mixtures and such. The best timing I could come up with was 28 degrees advanced at initial. I am going to monkey around with the idle speed/mixtures and timing tonight to see if I can get the timing within a more tolerable range.

Basically I am just going to run the hell out it, basically a tank gas, and then recheck plugs/compression/timing to see if anything gets any better. On a side note I contacted member wsa111 to see if he could tune the dizzy. He got back to me right away and we discussed my options. Heck of a nice guy. I will probably send the dizzy to him in a week or two.

First the bad.... I performed a leak down test on the motor yesterday dry/wet. On the dry test I found cylinders 1 and 3 to be perfect however 2,4,5,6 were only at best 65%. I had a stethoscope and was listening for blow by on the valves with no luck. On the wet test all cylinders were good. So that tells me the molley rings haven't seated yet.

Good news... I got the motor up and running and took it around my test loop twice. Initially I had the same stumble and hesitation at low RPM, but got it better with adjusting the mixtures and such. The best timing I could come up with was 28 degrees advanced at initial. I am going to monkey around with the idle speed/mixtures and timing tonight to see if I can get the timing within a more tolerable range.

Basically I am just going to run the hell out it, basically a tank gas, and then recheck plugs/compression/timing to see if anything gets any better. On a side note I contacted member wsa111 to see if he could tune the dizzy. He got back to me right away and we discussed my options. Heck of a nice guy. I will probably send the dizzy to him in a week or two.

PSIG

Well-known member

Moly-faced or filled rings seat immediately, and part of why they're so popular. It's a sacrificial coating applied to the ring face to lubricate and quickly conform to the cylinder, for immediate sealing and minimal chance for scoring. As it wears away so quickly, as does the fresh cross-hatch on the cylinder walls, I try to get my ring-seating load cycles in as soon as it's warmed on first startup. Cylinder finish is specific for different ring types, so I make sure to apply what the moly rings require, per the manufacturer's instructions for optimal break-in and life.So that tells me the molley rings haven't seated yet.

So, you found optimal idle timing, and now you can set total timing (which will reduce idle timing) and let manifold vacuum advance pull the idle timing up - as one option until you can reconfigure your distributor. At this point (assuming you checked your timing marks are accurateThe best timing I could come up with was 28 degrees advanced at initial.

Sickboy49

Well-known member

The engine builder told me they would not be totally seated in until I drove the car around 500 miles.Moly-faced or filled rings seat immediately, and part of why they're so popular. It's a sacrificial coating applied to the ring face to lubricate and quickly conform to the cylinder, for immediate sealing and minimal chance for scoring. As it wears away so quickly, as does the fresh cross-hatch on the cylinder walls, I try to get my ring-seating load cycles in as soon as it's warmed on first startup. Cylinder finish is specific for different ring types, so I make sure to apply what the moly rings require, per the manufacturer's instructions for optimal break-in and life.

So, you found optimal idle timing, and now you can set total timing (which will reduce idle timing) and let manifold vacuum advance pull the idle timing up - as one option until you can reconfigure your distributor. At this point (assuming you checked your timing marks are accurate), you can see the effect of timing on torque, but most of your issues appear to be air (leak) or fuel-based. For engine safety, I would set the total timing and work on fuel and air.

PSIG

Well-known member

Probably used a generic hone/plateau finish that will prolong ring seating. Or, he might have meant manganese phosphate ring coating (similar but different). With the proper finish, seating of moly rings is almost right now when loaded properly for break-in.

Hastings Rings recommended one-gear accel/decel from 2000-4000 rpm for loading/vacuum, increasing from half-throttle across several cycles to full throttle (if safe to do so). I prefer 2nd gear to avoid wheelspin or excessive speed, but do your thing.EngineBuilderMag.com said:This brings us to how the engine should be run after initial startup. The ideal combination is to tune the engine so that it starts on the first or second revolution. For carbureted engines, this means pre-filling the fuel bowls and accurately setting the initial timing. As soon as the engine starts, immediately bring it up to an above-idle speed. According to JE’s Senior Technical Account Manager Alan Stevenson, “You don’t want to break-in an engine at idle. You want to keep the rpm above 1,500 and vary the speed continuously for about the first 20 minutes.” After bringing the engine up to normalized coolant and oil temperature, put the engine under load. The cylinder pressure from 50 to 75 percent and eventually to 100 percent load will place additional pressure on the back side of the rings which will quickly establish the proper wear pattern for seating. With today’s rings, especially moly-faced versions, this can be achieved in a very short period of time and certainly within 20 to 30 miles of street driving. In WOT dyno testing, likely the rings are seated by the end of the first few runs. (https://www.enginebuildermag.com/2018/05/how-to-break-in-your-piston-rings-the-right-way/)