Not mine just sharing from VM6 facebook group.

OK Folks! Time for an update as well as some questions for the group.

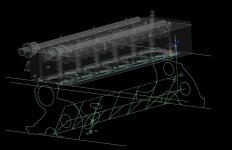

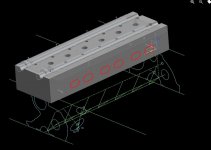

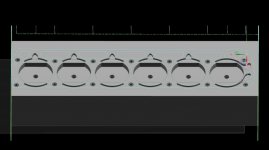

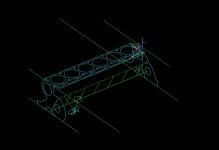

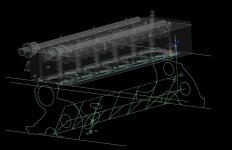

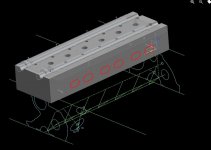

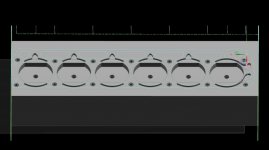

First for the update. Cylinder head design is progressing smoothly. One of the decisions that was made was to use the same intake port pattern/geometry and mounting configuration for the 2JZ intake manifold (It's an oval). The reason for this is be able to bolt on a variety of aftermarket intake manifolds depending on what the end user wants to use. That being said, the decision was also made to design a simple 4 barrel intake manifold that uses this same port design and bolt pattern so that the folks who want to stick with a carbureted configuration, TBI configuration, supercharged configuration, 1V, 2V, 4V or whatever style they currently employ, they can do so provided they get the new intake manifold. Keep in mind that the priorities of this new head are:

- MAXIMUM potential performance

- Backwards compatibility and aftermarket compatibility

Now for the first of three questions. I had already asked this in my last video going over some of the design rationale of this head, but I'll ask it explicitly here. At the back of the block at the last main bearing and last cam bearing, the oil passages form a sort of love triangle not seen anywhere else in the block where the oil passage that comes down from the head and intercepts the cam bearing. The weird part is that this passage actually extends further down (after going around the cam itself) to connect with the main oil supply passage. Does anyone have any insight into why this might be? My initial thoughts are to provide more oil pressure and flow to the head.

Now for the second question. I've been playing with the cooling passages in the head, including the passages on the deck face. So if any of you are familiar with the 2JZ, you'll know it's significantly wider than than the 200 and not being a pushrod engine, doesnt have to make room (AKA holes) in the block for pushrods and their movement, meaning the deck cooling passages have a relatively decent amount of room to be there. The 200 doesn't have that luxury and I have honestly been considering removing the deck coolant passages I have rough modeled in at the moment when I start to look at the amount of space left for a head gasket, sleeving, o-ringing the cylinders, etc and letting the coolant do the work from internal passages in the head. What are your guys' thoughts on the necessity of the deck coolant passages since the 200 didn't have them? I'd also be interested to hear your thoughts on this with respect to aluminum AND cast iron.

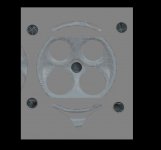

The last question concerns the oil pump. Now it is a goal of mine to get rid of the cam shaft and put in a dummy cam for stiffening so the timing chain and timing chain cover can be removed and all replaced with a belt drive system for the DOHC. However, this leaves the question of how to drive the oil pump and distributor. I had considered adding a pulley wheel to the dummy cam and leaving the distributor gear there, which would then drive the oil pump and distributor. However, the front of that cam is not meant to keep oil inside the block. Any suggestion on this front to perhaps seal that dummy cam? I'd personally like to do away with the oil pump and distributor altogether but I know that will alienate a lot of people so it's here to stay. I haven't looked into this problem that much yet if I'm being honest but it's been on my mind and I wanted to get some suggestions from the group before it starts banging down my door. Maybe a 2JZ-esque front plate oil pump design to replace the timing chain cover and old school oil pump?

Excited to hear your thoughts.

Jon