Baxsie

Well-known member

So in my ignorance, I did not know that there were small and big block Ford sixes. D'oh.

So I ordered the Holley Autolite 1100 EFI and a full HyperSpark setup.

The first challenge was the distributor, but I have modded it to fit the 240 - I owe the forum a write-up of that side project.

Now that I have the distributor hurdle working, I pulled off the old carb, and f*ck, the Holley EFI does not fit. New layers of my ignorance keep getting uncovered. I had measured as close as I could and I thought that the stud spacing lined up but that is not the case.

Some background information:

So I see two possibilities.

OPTION ONE: Ream out the holes a little bit on the Holley AutoLite 1100 throttle body, put it on the stock manifold, pat myself on the back and say it is good enough. One benefit is that the stupid amount I have already spent does not have to increase.

QUESTIONS FOR OPTION ONE:

QUESTIONS FOR OPTION TWO:

Any advice, mockery, or helpful suggestions would be appreciated.

So I ordered the Holley Autolite 1100 EFI and a full HyperSpark setup.

The first challenge was the distributor, but I have modded it to fit the 240 - I owe the forum a write-up of that side project.

Now that I have the distributor hurdle working, I pulled off the old carb, and f*ck, the Holley EFI does not fit. New layers of my ignorance keep getting uncovered. I had measured as close as I could and I thought that the stud spacing lined up but that is not the case.

Some background information:

- This is just an errand truck so I am not too stressed about performance. Although . . . I do sometimes tow the boat and it would not be a bad thing to have some extra power. I absolutely do not want to lose any power.

- The engine is just stock. I can see an 060 or maybe 090 on the #1 piston so I assume it was bored over some on the last rebuild. Stock cam, stock rockers, etc.

So I see two possibilities.

OPTION ONE: Ream out the holes a little bit on the Holley AutoLite 1100 throttle body, put it on the stock manifold, pat myself on the back and say it is good enough. One benefit is that the stupid amount I have already spent does not have to increase.

QUESTIONS FOR OPTION ONE:

- Would this at least option keep the power I have? The Holley AutoLite 1100 throttle body is so small.

- Would I lose power?

- Would the Holley AutoLite 1100 throttle body be the limiting factor?

QUESTIONS FOR OPTION TWO:

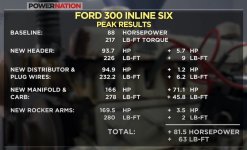

- If I did all this, could I expect a good power gain?

- How much is the factory log manifold the limiting factor on the 240?

- Is there an easy way to increase valve performance with ratio rockers? I do not want to remove the head.

Any advice, mockery, or helpful suggestions would be appreciated.