kjacobson351

New member

Hi all.

I poked my head in around about 6 months ago asking about supercharging the old 200. Since then I have swapped out the old crash box 3 speed on my econo to a 3.03 and I came across and installed a 9 inch out of 68 mustang with 31 spline axles and a limited slip diff. I now feel comfortable to start hot rodding the 200 now that the rest of the drivetrain is bullet proof.

I also managed to bring back a Gen 5 M90 off off a 2006 Pontiac Grand Prix GTP in my checked baggage coming back to Japan after a business trip in the states. I've been building this thing in my head forever but now I finally have the parts in hand. This will be a very slow process and I don't really even expect to be ready to use for the next year or two. But I will be posting here when I make progress here and there.

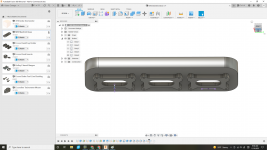

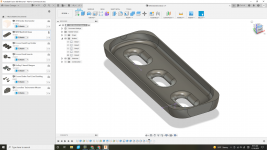

I have been doing a lot of 3d modeling and 3d printing and have been dabbling in casting aluminum so hopefully I will be able to incorporate some of those skills on this build.

Goals: Snappy and unique 200 build for my nearly daily driven 1961 Econoline + blower whine. Peak power is not the goal, in fact despite the plans to supercharge this I want to error on the side of safe because parts are very expensive to ship over here. I just want to have some fun and make some cool noises.

Fuel: I plan on buying a Holley 2300 Super Sniper ( I guess the regular 2bbl sniper is not ideal for draw through boost)

Intake: This is where I am somewhat stuck. I have a small log head. I was planning on installing 3 2300 flanges on the top of my log to give a sturdy base to mount an intermediary M90 manifold but I am not seeing any small log heads with a true 2v conversion. Has it been done? Can it be done?

I would also like to run 3 2300 flanges on my log because if the blower does not work out I can always cap off the side flanges and run the sniper directly on the middle flange.

Worst case scenario I can mill off the whole side of the head like in the May 1960 Hot Rod magazine but I really do not want to make my own header.

Blower Drive: I'm thinking about getting a universal serpentine pulley and mount it to my balancer with the 3 pulley bolts, or running a later model ozzy serpentine style balancer and running all of my accessories off of that. (Water pump may be tricky...)

Here are some pics of the blower, the rig, and what I am thinking as far as mounting the m90. Just hung up on whether or not I can get 3 2300 flanges on a small log at this point.

P.S be prepared to see this thread resurrected every now and again.

I poked my head in around about 6 months ago asking about supercharging the old 200. Since then I have swapped out the old crash box 3 speed on my econo to a 3.03 and I came across and installed a 9 inch out of 68 mustang with 31 spline axles and a limited slip diff. I now feel comfortable to start hot rodding the 200 now that the rest of the drivetrain is bullet proof.

I also managed to bring back a Gen 5 M90 off off a 2006 Pontiac Grand Prix GTP in my checked baggage coming back to Japan after a business trip in the states. I've been building this thing in my head forever but now I finally have the parts in hand. This will be a very slow process and I don't really even expect to be ready to use for the next year or two. But I will be posting here when I make progress here and there.

I have been doing a lot of 3d modeling and 3d printing and have been dabbling in casting aluminum so hopefully I will be able to incorporate some of those skills on this build.

Goals: Snappy and unique 200 build for my nearly daily driven 1961 Econoline + blower whine. Peak power is not the goal, in fact despite the plans to supercharge this I want to error on the side of safe because parts are very expensive to ship over here. I just want to have some fun and make some cool noises.

Fuel: I plan on buying a Holley 2300 Super Sniper ( I guess the regular 2bbl sniper is not ideal for draw through boost)

Intake: This is where I am somewhat stuck. I have a small log head. I was planning on installing 3 2300 flanges on the top of my log to give a sturdy base to mount an intermediary M90 manifold but I am not seeing any small log heads with a true 2v conversion. Has it been done? Can it be done?

I would also like to run 3 2300 flanges on my log because if the blower does not work out I can always cap off the side flanges and run the sniper directly on the middle flange.

Worst case scenario I can mill off the whole side of the head like in the May 1960 Hot Rod magazine but I really do not want to make my own header.

Blower Drive: I'm thinking about getting a universal serpentine pulley and mount it to my balancer with the 3 pulley bolts, or running a later model ozzy serpentine style balancer and running all of my accessories off of that. (Water pump may be tricky...)

Here are some pics of the blower, the rig, and what I am thinking as far as mounting the m90. Just hung up on whether or not I can get 3 2300 flanges on a small log at this point.

P.S be prepared to see this thread resurrected every now and again.