The Ford Falcon News

JimG Sun Aug 28, 2011

I'll post pictures as soon as I can take them. Basically though, I blocked the two passages that terminate in the Spark Control valve cavity, and the one behind the Distributor Vacuum outlet on the passenger side of the carb (the horizontal passage that goes into the venturi). I did this by drilling a shallow hole into the end of the existing passage with a #35 drill, tapping it to 6-32, and screwing a 6-32 X 1/8 brass set screw into the end of the passage, thereby blocking it.

JimG Aug 28, 2011

OK, as promised, I got the pictures taken today.

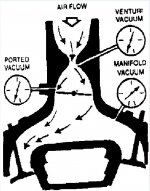

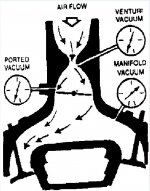

First, some background for those who've forgotten this stuff. Ported vacuum isn't rocket science. You just create an orfice in the venturi just above the throttle plate. You then create the necessary passages to connect the orfice to an outlet fitting.

Our Spark Control 1100s already have this. The problem is, it has some "extra" passages that must be blocked if we want ported vacuum.

JimG Aug 28, 2011

"Here is a photo I took that illustrates where all the passages go. The yellow part is the path we need for ported vacuum to work. The red paths must be blocked."

JimG Aug 28, 2011

DISCLAIMER: I've done this modification exaclty once, so I don't claim to be an expert. Your carb might be different than mine. All I can say is this: I made this modification, and it worked on my carb. Double-check your carb before you attempt this. Something might be different. Caveat Emptor!

JimG Aug 28, 2011

Next, the passage that connects to the rear of the spark control cavity.

If you think you'll ever want to return the carb to its previous "spark control" configuration, this is important. Otherwise, you can skip it. Measure the orfice in the brass insert shown. I used numbered drill bits and incorporated the go/no go method. The orfice in my carb was .032. Write this measurement down somewhere and keep it safe.

JimG Aug 28, 2011

Drill out the orfice and drill a shallow hole with a #36 drill bit. Tap to 6-32. Insert set screw as shown.

If you ever want to return the carb to Spark Control, just drill a hole in the set screw that's the same diameter as original orfice (in my case, .032"). This is where brass set screws are nice; they drill out so easily.

In this photo, the path for your ported vacuum is the center port, across the "trench" in the main body, and out the port near the bottom of the photo.

JimG Aug 28, 2011

One more port to block. Remove any brass fitting on the Load-O-Matic outlet on the passenger side of the carb. You'll be drilling, again, with a #36 bit straight into the Load-O-Matic outlet, blocking the port shown by the paperclip in this photo. Again, drill a shallow hole, tap to 6-32, and insert a set screw.

Unfortunately, I couldn't get a good shot of the set screw inside the Load-O-Hole, but I think you get the idea from looking at the previous photos.

Below is what I did when my 1100 had vacuum to the vacuum advance unit at idle after the JimG modifications.

There is a brass plug on the side of 1100 that can be removed to drill a new throttle bore vacuum port above the old one. JB Weld can be used to plug the old port. The plugged port is marked in blue You just need the port high enough to not have vacuum at idle. The new port could be lower than the one that I drilled.

I used a 6-32 Phillips head screw to block the venturi port instead of a plug that might fall into the carb.

Danville, Virginia, JimG's Falcon Sun Aug 28, 2011

Here's a shot of The Bird with the wideband sensor at the tailpipe.

JimG Sun Aug 28, 2011

I'll post pictures as soon as I can take them. Basically though, I blocked the two passages that terminate in the Spark Control valve cavity, and the one behind the Distributor Vacuum outlet on the passenger side of the carb (the horizontal passage that goes into the venturi). I did this by drilling a shallow hole into the end of the existing passage with a #35 drill, tapping it to 6-32, and screwing a 6-32 X 1/8 brass set screw into the end of the passage, thereby blocking it.

JimG Aug 28, 2011

OK, as promised, I got the pictures taken today.

First, some background for those who've forgotten this stuff. Ported vacuum isn't rocket science. You just create an orfice in the venturi just above the throttle plate. You then create the necessary passages to connect the orfice to an outlet fitting.

Our Spark Control 1100s already have this. The problem is, it has some "extra" passages that must be blocked if we want ported vacuum.

JimG Aug 28, 2011

"Here is a photo I took that illustrates where all the passages go. The yellow part is the path we need for ported vacuum to work. The red paths must be blocked."

JimG Aug 28, 2011

DISCLAIMER: I've done this modification exaclty once, so I don't claim to be an expert. Your carb might be different than mine. All I can say is this: I made this modification, and it worked on my carb. Double-check your carb before you attempt this. Something might be different. Caveat Emptor!

JimG Aug 28, 2011

Next, the passage that connects to the rear of the spark control cavity.

If you think you'll ever want to return the carb to its previous "spark control" configuration, this is important. Otherwise, you can skip it. Measure the orfice in the brass insert shown. I used numbered drill bits and incorporated the go/no go method. The orfice in my carb was .032. Write this measurement down somewhere and keep it safe.

JimG Aug 28, 2011

Drill out the orfice and drill a shallow hole with a #36 drill bit. Tap to 6-32. Insert set screw as shown.

If you ever want to return the carb to Spark Control, just drill a hole in the set screw that's the same diameter as original orfice (in my case, .032"). This is where brass set screws are nice; they drill out so easily.

In this photo, the path for your ported vacuum is the center port, across the "trench" in the main body, and out the port near the bottom of the photo.

JimG Aug 28, 2011

One more port to block. Remove any brass fitting on the Load-O-Matic outlet on the passenger side of the carb. You'll be drilling, again, with a #36 bit straight into the Load-O-Matic outlet, blocking the port shown by the paperclip in this photo. Again, drill a shallow hole, tap to 6-32, and insert a set screw.

Unfortunately, I couldn't get a good shot of the set screw inside the Load-O-Hole, but I think you get the idea from looking at the previous photos.

Below is what I did when my 1100 had vacuum to the vacuum advance unit at idle after the JimG modifications.

There is a brass plug on the side of 1100 that can be removed to drill a new throttle bore vacuum port above the old one. JB Weld can be used to plug the old port. The plugged port is marked in blue You just need the port high enough to not have vacuum at idle. The new port could be lower than the one that I drilled.

I used a 6-32 Phillips head screw to block the venturi port instead of a plug that might fall into the carb.

Danville, Virginia, JimG's Falcon Sun Aug 28, 2011

Here's a shot of The Bird with the wideband sensor at the tailpipe.

Last edited: