Help with information and/or AVAILABLE Cam selection for boosted small block six 250 appreciated, anecdotes not so much :

Basic SPECS, add'l as needed :

250 Small Block Six

Clean - 'low miles' D7xx stock block / brgs / Pistons.

D0xx Cyl head , 54 cc chambers , V8 springs, spring ringed seals w/machined seats, Back cut valves , ARP bolts , Composite Gskt.

Currently working on Direct - Mounting the 2Bbl Carb on the D0xx head.

(SCR = @ 8.7 : 1 by most calcs'.)

Vortech V2 Supercharger with pulley ratio optimizes 3-5 K RPM powerband.

Into Maverick with T5z OD , 3.80 Rear

.

.

( Holley 2300 modified for Blow-Thru BPV PV , Sealed shafts , Smoothed and Xtension tube into charge pipe, FP Ref' port in hat area, BOV current limit @ 6-8 PSI .

Currently 2Bbl adapter into original Single Barrel manifold intake. )

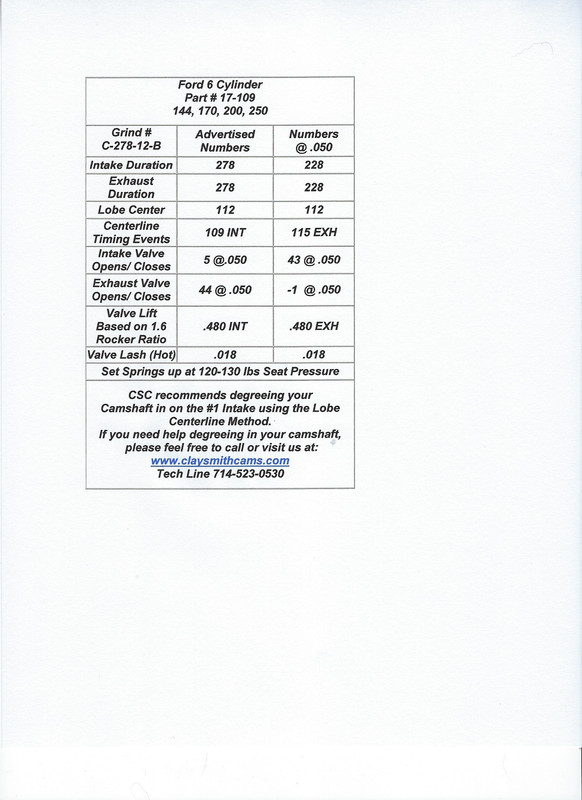

Also working on cam selection for previous Draw-Thru Turbo setup to use with a 200 or 250 and set of FORGED TRW pistons with similar other specs.

.

.

thanks

Basic SPECS, add'l as needed :

250 Small Block Six

Clean - 'low miles' D7xx stock block / brgs / Pistons.

D0xx Cyl head , 54 cc chambers , V8 springs, spring ringed seals w/machined seats, Back cut valves , ARP bolts , Composite Gskt.

Currently working on Direct - Mounting the 2Bbl Carb on the D0xx head.

(SCR = @ 8.7 : 1 by most calcs'.)

Vortech V2 Supercharger with pulley ratio optimizes 3-5 K RPM powerband.

Into Maverick with T5z OD , 3.80 Rear

.

.

( Holley 2300 modified for Blow-Thru BPV PV , Sealed shafts , Smoothed and Xtension tube into charge pipe, FP Ref' port in hat area, BOV current limit @ 6-8 PSI .

Currently 2Bbl adapter into original Single Barrel manifold intake. )

Also working on cam selection for previous Draw-Thru Turbo setup to use with a 200 or 250 and set of FORGED TRW pistons with similar other specs.

.

.thanks