Pmuller9

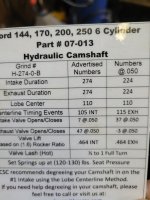

The cam is a clay smith H-274-O-B

I carefully found TDC on the number one piston using a dial indicator and adjusted the pointer and degree wheel to 0. I then carefully aligned a pushrod and the dial indicator in the intake lifter for the #1 cylinder and rotated clockwise to max lift. Zeroed the indicator and rotated .050 clockwise. The wheel read 158. I then rotated clockwise to max lift again. Rotated the crank counter clockwise .050 from the rear of the engine using a prybar and 2 flex plate bolts as to not loosen the crank bolt that was holding on the degree wheel. That gave me a figure of 64 degrees. 158+64=222/2=111.

You may be the victim of accumulated error.

Zeroing the degree wheel:

You bring the piston up to TDC and zero the dial indicator and at the same time adjust the pointer to "0" on the wheel.

Then turn the crank CCW until the dial goes past .050"

Now turn the crank CW until the dial reads .050"

The reason for pushing the piston up to .050" is to eliminate the rod bearing clearance error.

Continue turning the crank CW and go past TDC and past .050" on the other side, then turn the crank CCW to push the piston up to .050" on the dial.

If the wheel is truly at zero, both the reading before and after TDC should be the same and close to 12.5 degrees before and after TDC.

Camshaft Timing:

The camshaft should be timed using the .050" duration method.

That is the reason for the opening and closing points shown on the cam card.

This time zero the dial when the lifter is all the way down on the heel of the cam.

Then turn the crankshaft CW until the dial reads .050" and record the wheel reading.

Continue turning the crank CW.

The dial will go past max lift and down.

When the dial reads .050" from the bottom, record the wheel reading.

It is IMPORTANT that the crank is alway being turned clockwise when taking degree wheel readings, so the timing chain slack doesn't introduce an error.

If you accidentally go past the .050" on your dial, back the crank up CCW and come back into the .050" reading CW.

If you look at the cam card, the first intake .050" reading as the lifter rises is at 7 degrees BTDC and is .050" from the bottom after max lift at 37 degrees ABDC.

Check the exhaust reading also just to see if the lobe separation angle is correct on the cam.

The exhaust opens 47 degrees BBDC and closes 3 degrees BTDC