Some updates for everyone here.

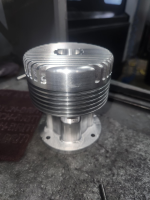

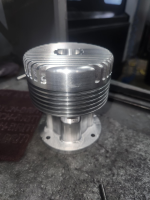

We just scored a major sales agreement with a drone manufacturing company. I'm under an NDA so I cant say who. This is for scotch yoke type naturally aspirated engines 125cc in displacement. I've attached some pictures.

I was also able to purchase the original Bourke 400. What a beast, look at the size of those wrist pins! I'll be rebuilding it and doing testing sometime in the future.

I was also able to purchase the original Bourke 400. What a beast, look at the size of those wrist pins! I'll be rebuilding it and doing testing sometime in the future.

Today I attempted to complete the last step in making the new spindle nut. Its almost complete. We have two Okuma MC 4 VAE milling centers. We purchased them from Designs For Tomorrow. One of them has a fourth axis attachment. Today we attempted to load G-code into one using the floppy drive. We inserted the floppy disc into the disc drive, turned on the machine, and it said "Control Floppy Loading Wait" We waited ten minutes, nothing happened. We turned off the machine, removed the floppy disc from the drive, waited thirty seconds, and turned it on again. Same thing. This was a perfectly functioning machine. We need to get installation floppy drives to re-install the parameters. So my day yesterday and today was not good.

Today I attempted to complete the last step in making the new spindle nut. Its almost complete. We have two Okuma MC 4 VAE milling centers. We purchased them from Designs For Tomorrow. One of them has a fourth axis attachment. Today we attempted to load G-code into one using the floppy drive. We inserted the floppy disc into the disc drive, turned on the machine, and it said "Control Floppy Loading Wait" We waited ten minutes, nothing happened. We turned off the machine, removed the floppy disc from the drive, waited thirty seconds, and turned it on again. Same thing. This was a perfectly functioning machine. We need to get installation floppy drives to re-install the parameters. So my day yesterday and today was not good.

Regardless, here are the updates. Tomorrow I will begin welding together a testing stand for the Bourke 400.

I've also attached a photograph of a side project, an electrically de-coupled Tesla turbine type internal combustion woodchip fired gas turbo-generator for stationary CHP applications. A PDF describing it is attached.

We just scored a major sales agreement with a drone manufacturing company. I'm under an NDA so I cant say who. This is for scotch yoke type naturally aspirated engines 125cc in displacement. I've attached some pictures.

I was also able to purchase the original Bourke 400. What a beast, look at the size of those wrist pins! I'll be rebuilding it and doing testing sometime in the future.

I was also able to purchase the original Bourke 400. What a beast, look at the size of those wrist pins! I'll be rebuilding it and doing testing sometime in the future.

Today I attempted to complete the last step in making the new spindle nut. Its almost complete. We have two Okuma MC 4 VAE milling centers. We purchased them from Designs For Tomorrow. One of them has a fourth axis attachment. Today we attempted to load G-code into one using the floppy drive. We inserted the floppy disc into the disc drive, turned on the machine, and it said "Control Floppy Loading Wait" We waited ten minutes, nothing happened. We turned off the machine, removed the floppy disc from the drive, waited thirty seconds, and turned it on again. Same thing. This was a perfectly functioning machine. We need to get installation floppy drives to re-install the parameters. So my day yesterday and today was not good.

Today I attempted to complete the last step in making the new spindle nut. Its almost complete. We have two Okuma MC 4 VAE milling centers. We purchased them from Designs For Tomorrow. One of them has a fourth axis attachment. Today we attempted to load G-code into one using the floppy drive. We inserted the floppy disc into the disc drive, turned on the machine, and it said "Control Floppy Loading Wait" We waited ten minutes, nothing happened. We turned off the machine, removed the floppy disc from the drive, waited thirty seconds, and turned it on again. Same thing. This was a perfectly functioning machine. We need to get installation floppy drives to re-install the parameters. So my day yesterday and today was not good.Regardless, here are the updates. Tomorrow I will begin welding together a testing stand for the Bourke 400.

I've also attached a photograph of a side project, an electrically de-coupled Tesla turbine type internal combustion woodchip fired gas turbo-generator for stationary CHP applications. A PDF describing it is attached.