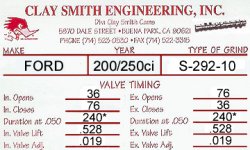

Hi xctasy and Ford Six members, after re-reading through Xctasy's above post from (https://fordsix.com/threads/ford-inline-six-build-on-engine-gremlins.84399/#post-678763) yesterday this sparked some thoughts and put me onto researching what the Max Valve Lift you could get on any of Ford Small Six's. This research is for a current 200 six build as well as another in the planning on trying to get more total valve lift with a parts combo used on the Ford Small Six Large Log Head's. I am wondering what is the maximum of Camshaft Lobe Lift size is that can fit into the Short Blocks Camshaft Tunnel? The highest lobe that I have found listed for any of the off the shelf Camshaft Grinds seems to be a .330 Camshaft Lobe (this gives you a total Lift is .545 when used with the 1.65 YellaTerra Roller Rocker Arm's) this is with the Clay Smith 292 Solid Lifter Grind has anyone been able to use any thing bigger in a block with a custom ground cam? I would like to see .600 or even more lift.Offset FE rocker tip/advice was made here at Ford Six back in 2016, using the David Vizard method of offset bushes. 67straightsix and I talked about it.

See post #41 in this thread

"https://fordsix.com/threads/high-ratio-rocker-arms.74180/page-3"

Last edited: