Hey All,

Hope you guys are all doing well during all this.

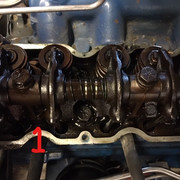

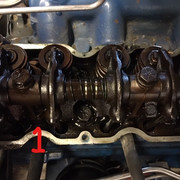

In a previous post I was asked if I had run a compression test and I wanted to follow up on that and let you all know my results and what feedback, hopefully good you can give me from the numbers. Also, I wanted to take a look at my valves just to learn similar to what DoctorC had posted a while back. I also want to paint the valve cover, it is a little beat up.

My initial thoughts/questions:

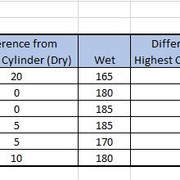

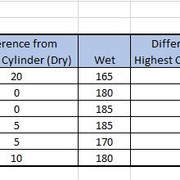

1. My #1 cylinder seems a little off, it is over 10% different from the highest and has a 10psi jump from dry to wet. Is this decent, or does something need to be done.

2. I get 10 to 15 psi differences on cylinders 3,4, and 6 as well. Decent, or do I need to replace the rings?

3. I have a little bit of 'crud' and where lip where the cover sits has remains of the gasket. Can I spray brake clean or simple green on this to clean it up?

4. Any painting tips?

5. I will likely start the engine up for about 20 seconds and look for oil coming out at the right places.

6. Lastly, should I adjust the valves? I have a torque wrench.

Thanks for reading. Edited because I forgot to include the test results.

https://ibb.co/bBZcppH

https://ibb.co/BsHty0x

https://ibb.co/D4wvRtS

https://ibb.co/1f0WMNj

https://ibb.co/MD3KnW0

Hope you guys are all doing well during all this.

In a previous post I was asked if I had run a compression test and I wanted to follow up on that and let you all know my results and what feedback, hopefully good you can give me from the numbers. Also, I wanted to take a look at my valves just to learn similar to what DoctorC had posted a while back. I also want to paint the valve cover, it is a little beat up.

My initial thoughts/questions:

1. My #1 cylinder seems a little off, it is over 10% different from the highest and has a 10psi jump from dry to wet. Is this decent, or does something need to be done.

2. I get 10 to 15 psi differences on cylinders 3,4, and 6 as well. Decent, or do I need to replace the rings?

3. I have a little bit of 'crud' and where lip where the cover sits has remains of the gasket. Can I spray brake clean or simple green on this to clean it up?

4. Any painting tips?

5. I will likely start the engine up for about 20 seconds and look for oil coming out at the right places.

6. Lastly, should I adjust the valves? I have a torque wrench.

Thanks for reading. Edited because I forgot to include the test results.

https://ibb.co/bBZcppH

https://ibb.co/BsHty0x

https://ibb.co/D4wvRtS

https://ibb.co/1f0WMNj

https://ibb.co/MD3KnW0